Nilpeter Hosts Open House at New North American Facility

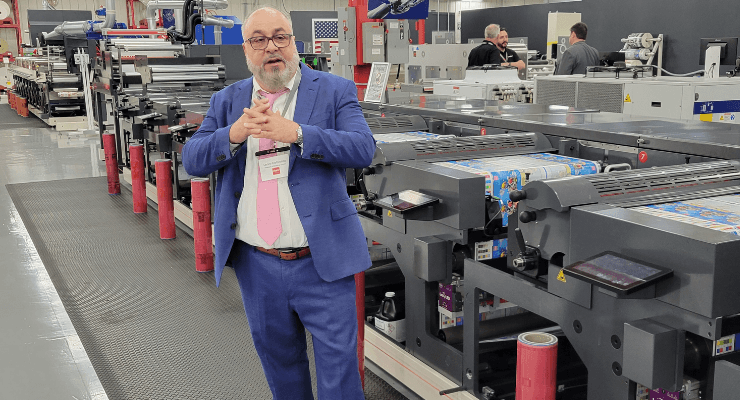

Lenny DeGirolmo showcases Nilpeter's automated capabilities at the event.

Greg Hrinya, Editor Label & Narrow Web 04.10.24

More than 150 attendees and industry partners got an up-close look at the manufacturer’s new Technology & Service Center in Cincinnati, OH, USA.

“The new press has been great for us,” explained Randy Ridge, general manager, International Label. “It’s been the first press like it in our market, and we wouldn’t have been able to hit our deadlines to take care of our customers without it. As it’s a hybrid flexo press with foiling capabilities, we’re running some really awesome jobs on it, as well.”

Nilpeter welcomed more than 150 label and package printing industry personnel to the unveiling of the company’s North American Technology & Educational Center. The Nilpeter Expanded Gamut Open House event, which took place on April 9, 2024, featured educational seminars, live product demonstrations and tours, and networking and collaboration.

This state-of-the-art center allows Nilpeter to highlight its expansive product portfolio, which includes flexo, digital, and value-added technologies, to the North American market.

“We want to educate and teach, and that’s what this new facility is all about,” says Lenny DeGirolmo, managing director of Nilpeter USA.

The facility, located at 11550 Goldcoast Drive in Cincinnati, OH, played host to a number of industry partners, including ACTEGA, BST North America, Flexo Wash, GEW, Multi-Plastics, Maxcess, Siegwerk, Techkon USA, and more.

Meanwhile, Lewis Cook, co-founder and CEO of Catapult Print, a label converter based in Orlando, FL, served as a keynote speaker, touching upon the use of “Expanded Color Gamut” (ECG) – also the event’s theme. Clemson’s Chip Tonkin, Techkon’s George Adam, and Flexografix’s Ken Pavett were also featured speakers at the event.

Cook touted the benefits of building Catapult’s successful converting model around Nilpeter’s printing press technology. “Catapult came to the market to change things we felt passionately about, and our model hinges around the Nilpeter presses,” remarked Cook. “Nilpeter has been an incredible partner to Catapult, and without these FA presses our model doesn’t work.”

When Catapult established its business in 2018, it came to market with zero customers. Utilizing a blank slate, the Orlando-based converter sought out the best technology with which to outfit its futuristic facility. At the time, Cook noted, there had not been much evolution in label printing, which he and his father and chairman, Mark, strived to change.

“We felt there was a gap in the label market, and we came to be a disruptor,” commented Lewis Cook. “We’ve been proven right, and our results show that. All of our growth has come organically, and we’ve become a $60 million business in six years. We have a 98% customer retention rate, and when we promise things, we truly deliver for the business.”

Catapult has created a model to limit variables across the business, sticking with a select few industry suppliers. The company fingerprints its Nilpeter presses on a monthly basis, establishing an analytical model to better understand how its presses are performing.

“We feel we have digitalized flexo with automation and auto-registration,” said Cook. “We regularly reduce jobs per month by 32% because we can run multiple SKUs across the web, which generates more uptime on our presses.”

Catapult produces 25 SKUs per day, per press, and 20 jobs per day on average. So far in Q1 of 2024, Catapult has shipped 9,300 SKUs. The average turnaround time on an order with the Nilpeter FA Line presses is six days, although numerous orders are turned around more quickly. According to Cook, Catapult has delivered 2,300 SKUs in 0-2 days, 755 in 3-4 days, and 6,250 in 5-8 days in Q1.

“These presses are like F1 cars to us,” exclaims Cook. “The support Nilpeter has given us on a monthly basis has been critical to our success. Our model, with Nilpeter, allows us to produce more with less. We’re always trying to push the envelope, and it’s great to have a partner in Nilpeter that’s also trying to push the envelope.

“The FA Line press is worth every penny that we’ve invested, and it pays back in dividends because of all the advantages of the press,” added Cook. “It’s about the benefits it brings your business.”

According to Pavett, Nilpeter’s presses have been optimized to deliver extraordinary color on labels and packaging. “Nilpeter’s technology features excellent manufacturing tolerances and build quality, holds superior registration accuracy, and have great experience and support with expanded gamut printing,” he noted. “Nilpeter knows their presses are going to reproduce ECG better than other presses out on the market. Nilpeter is an excellent fit for ECG because of its build quality and ability to hold registration.”

“ECG is necessary in packaging because many of the key brand colors are outside CMYK,” added Tonkin.

As part of the live product demonstrations, Nilpeter showcased the FA-17, FA-26, FB-350, and more. “This open house is a pivotal moment for Nilpeter to reinforce our global leadership,” states DeGirolmo. “Our goal is to support the growth of our customers in the labels and flexible packaging markets.”

Nilpeter’s technology proved popular among the 15- attendees, too. For example, International Label & Printing Co., based in Elk Grove Village, IL, installed the first hybrid press in North America featuring a partnership between Domino and Nilpeter.

“The new press has been great for us,” explained Randy Ridge, general manager, International Label. “It’s been the first press like it in our market, and we wouldn’t have been able to hit our deadlines to take care of our customers without it. As it’s a hybrid flexo press with foiling capabilities, we’re running some really awesome jobs on it, as well.”